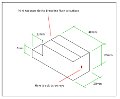

Beveller

Simple tool for slab builders

Lots of us do some slab building. To join two pieces at right angles, some prefer to lay flat slab to the edge of flat slab, and blend the two together. Others prefer to form a bevel on each piece and marry the bevels.

When I am building complex shapes I find it easiest to cut each piece to the finished visible size (without having to remember to subtract either one or two thicknesses) and join the slabs with a bevel.

Although they seem to fairly widely used, many people haven't used bevellers or even seen them. The beveller illustrated here is one that I normally use. The dimensions aren't that critical, but they are what I find comfortable to use. Little details to watch for are:

- Shallow groove in the bottom of the block, just the right size for the nylon/stainless line you are using.

- Screw eye on back of block.

- First end of nylon fastened round stem of screw eye.

- Take line round block, making sure it is in the groove underneath.

- Take two turns c/w round stem of screw eye, tie off line on ring of screw eye. This provides an easy method of tension adjustment on the line. If you are using nylon line, put a drop of nail varnish on the knot to stop it coming undone.

- I usually make the bodies from oak or similar hardwood.

In use I find that the small triangular offcut of clay forms a neat fillet to reinforce the inside of the joint.

Of course, if you build a lot of hexagons, just halve the length of the top overhang to produce a 60° edge.

Click on picture for enlarged version.